The beating heart of a li-ion

Advertorial: Every automotive vehicle has a battery of some form or other, from AGM, EFB, to lithium-ion (LI-ION), and EV applications. With any new vehicle innovation, the battery remains the beating heart.

What does good battery charging mean, why is it important and how should workshops be charging batteries to make sure that their vehicles remain on the road? Charging a battery is essential because it’s the source of all energy required for the infotainment, any heating, lighting and all other electrical features used while the car is running or idling.

To be future-ready, it’s important to invest in charging technology that is compatible with lithium-ion batteries, to ensure that you can look after plug-in hybrid and all-electric vehicles.

Chargers such as the Pro25S and SE and the Pro120, are capable of balancing and equalising batteries for the commercial vehicle sector and for independent workshops. They deliver 25A output charge and are excellent for showroom charging and all diagnostics supporting the 12V ranges.

The Pro25 series is compatible with all battery technologies from 40Ah-500Ah and has selectable power modes. It‘s a robust, rugged unit to handle tough environments, has 25A output and inbuilt safety and stability features.

Ken Clark, Managing Director at Rotronics, says: “When selecting the right charger or BSU for your workshop needs, it’s vital to be really clear on the application you’ll be using it for and know details such as, what consumer power demands are on the vehicle when carrying out software updates etc? How much time do I have to charge the battery (bigger charger capability, equals reduced charging times).

“Think clearly about these conditions and which vehicles you have coming into the workshop and what level of power supply is required, and what time constraints you may have. Once you know that, then the charger selection should be more obvious.”

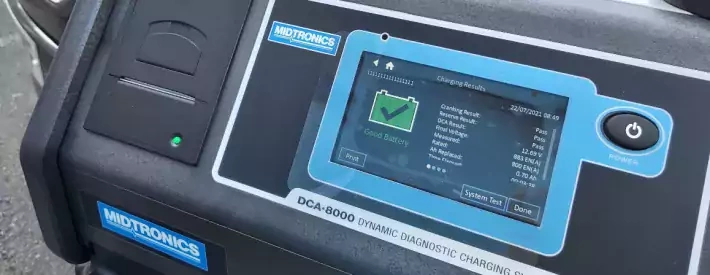

A charger with full diagnostic capabilities is the DCA8000 and it’ll provide complete test diagnostics of most battery types in up to two minutes and will then speedily charge accordingly.

Ken Clark adds: “The DCA8000 delivers accurate battery diagnostics, has the ability to detect failures and will support remote software updates. It has a great intuitive touchscreen and can calculate the charge time, so that can be built into everyday workshop activities.”

It’s worth paying attention to details like the length of the charger cables as some will not have sufficient length. Most have six metre cables but that is not standard on all chargers. You may need to have the ability to cope with 12V and 24V batteries.

Ken Clark says: “The Pro50-2, is the only charger compatible with 24V batteries that can deliver balanced charging with its unique twin output, either through 24V sets or two individual 12V vehicles at the same time. For the best safe charging, it blends charge acceptance and battery conditioning.”

Some chargers have inbuilt safety and security measures to limit the current going into the battery and most operate between 0.8amp and 2amp acceptance, before they go into supply/float mode. This is to stop thermal runaway, which is an accelerated process of increasing temperature releasing energy and therefore increasing the temperature further, leading to a destructive situation.

Ken Clark concludes: “Look after your investment, because any battery technology needs to be maintained to achieve long-term accuracy. It’s important to understand how frequently the units need to be serviced and calibrated – with some it’s every year. It’s also good to know if you can get part spares when required – not all will have spares. Can you get the units serviced and repaired?”

The Rotronics team can support most service, repair and calibration requirements, if you need to get some expert advice.

If you need to talk to one of the Rotronics team on the phone; please call 0121 526 8185 for more information. Go to www.rotronicsbms.com or email info@rotronicsbms.com.