How electrification is changing our approach to vehicle repair

What’s in this article: Powertrain technology is changing as electrification takes hold, but how will it change vehicle repair?

Electrified vehicles are becoming more of a common sight on the UK’s roads. Since the first hybrid-electric cars of 20 years ago, the technology has developed rapidly. With carbon dioxide tailpipe emissions targets getting more and more stringent, and the fines for breaching them increasing, most manufacturers now offer hybrids across their ranges. Some are going further still, Hyundai, Jaguar, Volkswagen, Porsche and many others offering purely electric vehicles.

An electric car poses quite a different challenge when it comes to accident repair than internal combustion engine car. Their power systems can prove hazardous to the unwary, with significant current required to drive their motors - touching the wrong thing can be very bad news. Richard Billyeald, chief technical officer at Thatcham Research, explains to MotorPro how electrification is beginning to change the face of vehicle repair.

“It’s about awareness. Knowing that this vehicle is electrified, and having the training to deal and repair it. We’re in the process of releasing some general guidance to the claims industry - not just repairers and insurers, but also emergency services, breakdown services - to create awareness around electrified vehicles.

“It starts with identification and understanding. If it’s a Tesla, that’s recognisable and you’ll be pretty certain that’s electrified. If it’s a VW e-Golf it might just look like a pretty standard Golf on the surface, so understanding that it has a few hundred volts in a battery pack is incredibly important.

“One of the things we try to keep a lid on is the hyperbole and fear around high-voltage electrified vehicles. If you think about combustion engine cars you have a tank full of highly volatile petrol - one of the most volatile substances out there - but no-one really worries about working on vehicles and the flammability risks, because those risks are built into the process. They’re very familiar, everyone understands them and works accordingly.

“With electrified vehicles there are risks, but as long as you understand them and know how to deal with them, then it isn’t a problem.

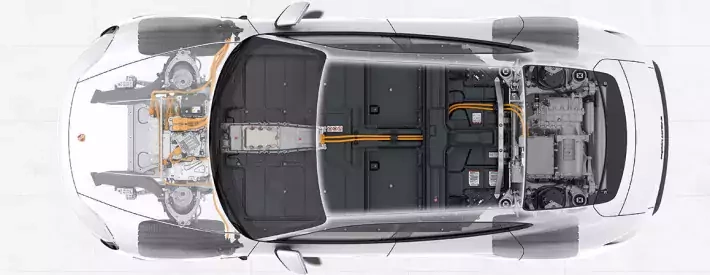

“Battery electric vehicles (BEV) that are designed as electric vehicles as opposed to converted combustion engine cars, are very different underneath. Most BEVs have what we call a skateboard architecture: the battery is mounted in the floor and represents a structural part of the car.

“What that means for repairers is when you get down into the structure, it’s fundamentally different from an combustion engine car and that needs to be understood. Then there’s the added complication of the awareness around several hundred volts in the battery or in the cabling that might be running through a sill.

“The batteries are key to the industry being able to deal with EVs. Manufacturer strategy around battery repairs is going to be important. On the face of it it’s a monolithic block, but actually once you get into it there are many elements. Batteries are vulnerable to a certain extent, but in the crash-testing we’ve done with electric vehicles, for EuroNCAP and general research, batteries are actually pretty well protected. You’ve got to have a pretty big accident to damage the battery, though things like going over kerbs and roadside furniture can have a direct impact on them.

“What the industry needs to evolve is the system for what to do with those batteries if they can’t be repaired. If the vehicle has to go for salvage can those batteries be repurposed to mitigate the loss, if it can’t be, then it needs to be recycled or disposed of correctly and that’s not necessarily straightforward.

“Having repair methods or the guidance to say this can be repaired and this can’t be, that’s what we want to see coming in from the manufacturers.”