Is Ignorance Bliss?

Advertorial: Every workshop’s worst battery nightmare is not being able to determine an accurate test result and having no confidence in the diagnosis of any battery fault.

There are lots of tools that can provide diagnostic tests regarding the electrical system, but when it comes to diagnosing battery faults it is not that easy. There are factors at play, such as the age of the battery, what kind of technology is being used and how it is going to be used. Is it an AGM/EFB/stop/start? The drive cycle of the vehicle is important to consider, ie how many miles each year will it cover? As is the type of route that it will be subjected to; short, stop/start journeys or long trips? And the seasonality plays a starring role in the battery’s performance.

Each one of these elements play a big role in the performance of the battery and we need to understand all the interconnections to get an accurate diagnosis. Getting to a clear grasp of all the elements in the mix and trying then to find some solutions without the best technology to hand, unfortunately means a lot of guesswork. At this stage, an accurate battery test is the only credible first step to solve the problem.

In testing any battery without suitable technology, we will get one of four results; good, bad, or good but needs charging. The fourth option is charge and re-test. This is a key area that we would need to focus on in terms of juggling all the above elements that are in play – because we are really entering into the unknown. Will charge and retest help make a decision for us and eliminate the guesswork?

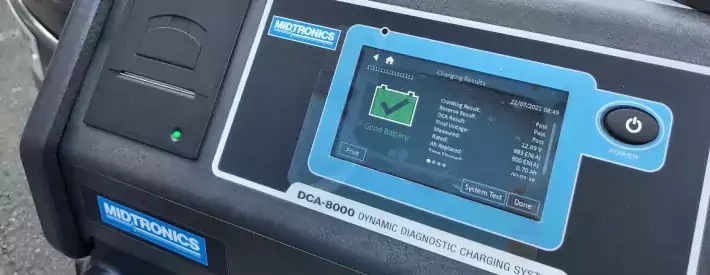

The battery experts at Rotronics are not so keen on guesswork and work with their workshop customers to help them achieve complete accuracy in the diagnosis of a problem. That then leads them to the best solution to fix it. Using technology like the DCA8000 is like having a battery expert resident in your workshop because it is the all-in-one solution.

The DCA8000 will deliver one of two results: good battery and fully charged or a straightforward replace decision. That is because it has done all the testing and diagnosis for you and then actioned any problems that it has found.

Ken Clark, Managing Director at Rotronics, says: “If a battery needs any form of charging, to recover it to a good state, the DCA8000 will do it automatically. It will take away any guesswork or the technician having to make a decision based on gut feel. It doesn’t require him or her to hook up a separate charger and use valuable time charging a battery that won’t recover.

“The DCA enables them to get on with the rest of his job without having to worry about battery charging. It tells the technician how long the charge will take so that he or she doesn’t have to keep going back to the job to check. Because of the DCA’s technology, which identifies charge acceptance, cranking and reserve capacity, you get a very accurate picture of what the batteries suitability is for any kind of vehicle, ICE, EV, hybrid etc.

“The DCA doesn’t have to plug in a variety of different technologies to do different jobs, it does all of this in the fraction of time, saving the technician valuable time. It is a fantastic all-in-one solution for a busy workshop which takes away any mystery about battery management.”